FLEX-FLASH® FLASHING

Submittal SheetsPDF Downloads

Safety Data SheetsPDF Downloads

LEED / TransparencyPDF Downloads

CADZIP Downloads

H&B's Flex-Flash® is a polyester scrim reinforced 40-mil thick product formulated with Elvaloy® Kee. It does not drool and combines the best features of other types of flashing, making it a truly superior product. Moisture infiltration can occur at sills, projections, recesses, intersections and mortar joints. The solution begins with proper flashing.

NO MORE DROOL!

- Extremely tough, with excellent impact and tear resistance

- Flexibility is maintained in all weather environments, even in extreme heat or cold

- Highly resistant to oils and will repel most chemicals

- Compatible with most silicone and urethane sealants

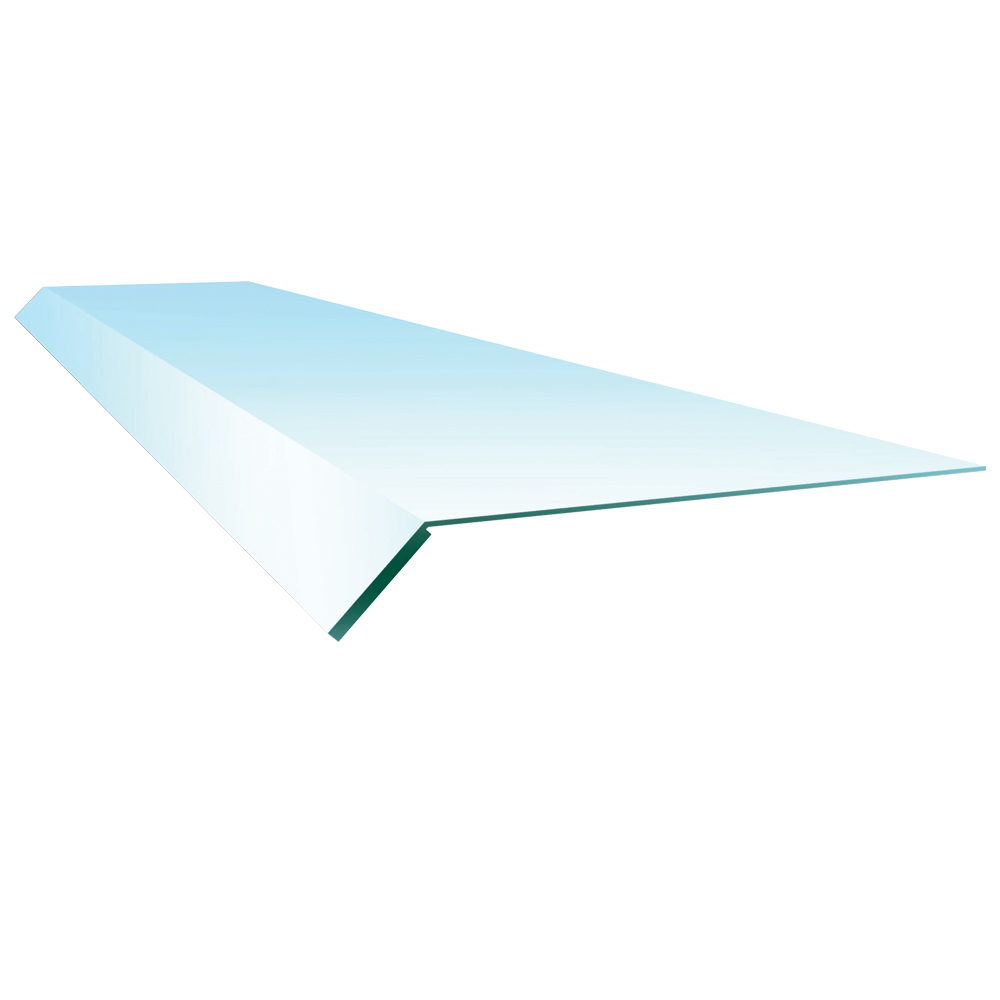

- Suitable for thru-wall or surface-mount applications

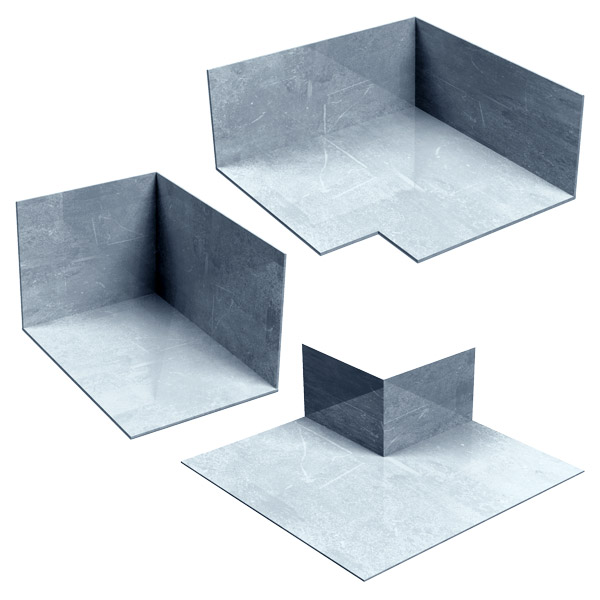

- Pre-formed seamless corners and end dams available upon request

- Not susceptible to degradation by UV

Typical "peel-and-stick" flashings have a black, rubberized-asphalt component that can "drool" or leach out to the exterior of the building in warm temperatures if not precisely installed. This can leave unsightly marks that are difficult to remove.

Flex-Flash® has a pressure-sensitive, clear adhesive that will not drool when exposed to UV or heat.

Flex-Flash® may be used in thru-wall or surface-mount applications. For surface-mount applications, apply to clean, dry surface.

For surfaces where additional adhesion may be required, use H&B Primer SA. Termination Bars must also be used. Flex-Flash should be extended beyond the wall face and cut flush with the brick. Optional Drip Plates may be used to effectively guide moisture to the exterior.

NOTE:

- U.S. Pat. No. 6,584,746

Other Patents Pending - Elvaloy is a registered trademark of the DuPont Company.

- This product carries a 10-year limited warranty.

FLEX-FLASH SEALANT COMPATIBILITY CHART

There are various locations in a wall system where the thru-wall flashing and a construction sealant are used together to form a weather-tight seal, i.e. relief angles, soft joints, door and window perimeters. Hohmann & Barnard's Flex-Flash Membrane is compatible and has been tested for adhesion and compatibility by various sealant manufacturers.

The listing below gives a selection of both silicones and urethanes that have been evaluated. In all cases, the sealant manufacturers application procedure should be followed and they recommend that field adhesion testing should be continued throughout all projects.

POLYETHER

| Company | Product |

| Hohmann & Barnard | HB Sealant |

SILICONES

| Company | Product | Primer Required |

| Dow Corning | 790 791 795 (Dark colors only; Black, Charcoal, or Bronze) | 1200 Prime Coat 1200 Prime Coat 1200 Prime Coat |

| G.E. Silicones | Silpruf | SS4179 |

| Pecora | 864NST 890NST 895NST AVB | None (P-120 may be used if desired) |

| Tremco | Spectrum 2 | #10 |

URETHANES

| Company | Product | Primer Required |

| SIKA | Sikaflex-1A | #260-205 |

| Sonneborn | Sonolastic NP1 | #733 |

NOTE: When using with insulation, please verify the compatibility with the manufacturer.